BONAR a.s.

We believe that our products and services will help you increase your competitiveness.

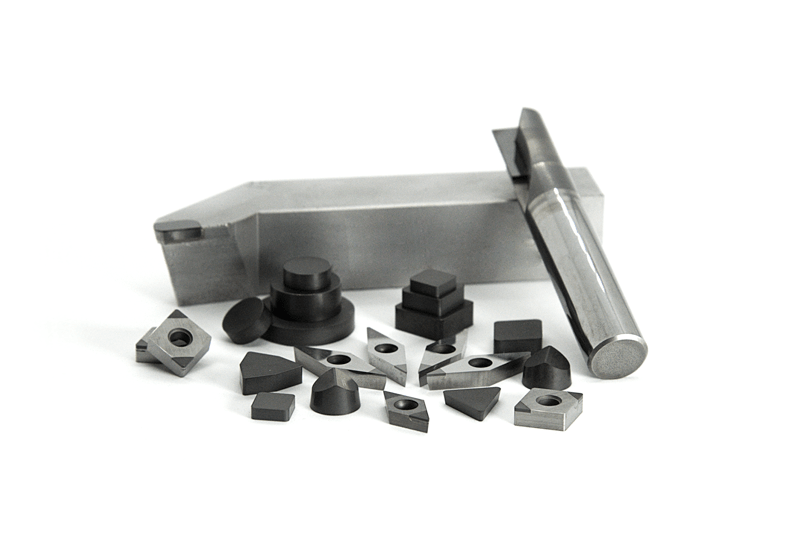

Grinding and renovation of monolithic replaceable PCBN inserts, embedded replaceable inserts and tools with PCBN and PCD material.

Welcome to the website of Bonar a.s.. Bonar a.s. was founded in 1997 in Šumperk.

OUR SERVICES

Grinding and renovation of monolithic replaceable PCBN inserts, embedded replaceable inserts and tools with PCBN and PCD material.

We are looking for a solution for a specific machining operation. Our active approach in selecting the appropriate tool, solving its geometry and production technology conditions for machining your products. It will allow you to choose the full use of the potentials of PCBN and PCD materials.

SHARPENING

Grinding of monolithic replaceable PCBN inserts, embedded replaceable inserts and tools with PCBN and PCD material.

By grinding inserts and tools in a timely and correct manner you can extend their service life and achieve savings on your machining.

RENOVATION

Renovation of monolithic replaceable PCBN inserts, embedded replaceable inserts and tools with PCBN and PCD material.

The optimal renovation variant will be agreed in consultation with the customer after the initial inspection and evaluation of the wear rate of inserts and tools.

Worn PCBN and PCD materials are replaced with new ones and subsequently re-grinded.

Inserts and tools are renovated as a whole or only in some stages of the cutting edges. With the right selected renovation you can gain a fully-fledged insert or tool and significantly improve your machining savings.

FREE TECHNOLOGY CAPACITIES

The company BONAR a.s. offers free capacities of these investments, which were acquired within the Operational Program Enterprise and Innovation for Competitiveness.

Name of the project, establishment of the VAV workplace BONAR a.s.

Project number CZ.01.1.02 / 0.0 / 16_092 / 0010039.

These spare capacities can be used in accordance with the condition of transparency and non-discrimination set out in the call for tenders.

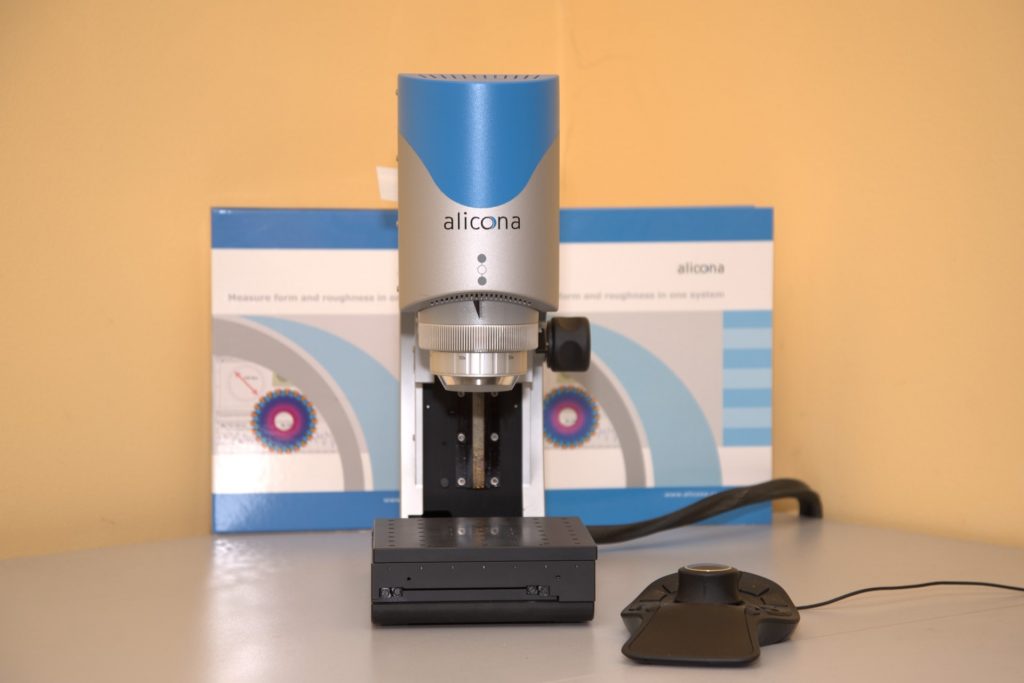

ALICONA INFINITE FOCUS-SL

Special microscope for checking the results (verifying the characteristics of the samples from the point of view of geometry and also the material structure).

- 3D measuring microscope for edge quality control

- Included control station

- Polarizer

- Lenses: 10X, 20X, 50X

- Grip for handling small objects

- Roughness measurement, edge quality measurement

Price 1500 CZK / Hour

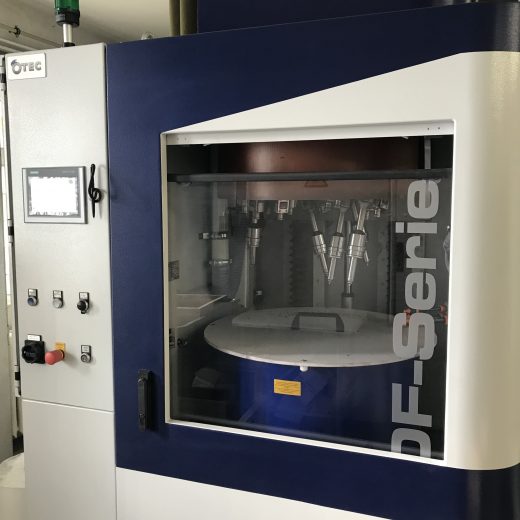

OTEC DF-3 WET

It is a special machine that is used to machine the workpiece by “immersing” it in a process container with an abrasive medium. Machining takes place by moving (dragging) the workpiece in an abrasive medium. The resulting degree of abrasion is determined by the nature of the medium and the machining time.

- Process container capacity: min 80 liters

- Process container height

- Lightweight construction

- Adjustable automatic change of direction of rotation

- Infinitely adjustable workpiece speed

- Program memory: min. 200

- Slow rotation function

- Maximum number of clamping heads: min. 3 pcs

- Possibility of lean of the clamping heads

- Possibility of dry and wet machining proces

- Machine accessories for the possibility of clamping inserts

- Basic abrasive media

Price 1400 CZK / Hour + Media wear

If you are interested, you can contact Mr. R. Velička and agree on the next step. Email - radek.velicka@bonar-as.cz.

ABOUT US

The company BONAR a.s. was founded in 1997 in Šumperk. Since its inception, the company has been producing a superhard material – polycrystalline cubic boron nitride (PCBN), using high-pressure synthesis technology.

We produce high-performance products from our own PCBN material – replaceable inserts in a monolithic design.

We embed replaceable inserts and tools for machining with PCBN and PCD material.

All our steps are aimed at our goal – to ensure the best results when using our products for you.

We renovate and grind inserts and tools made of PCBN and PCD. These operations can extend tool life and achieve savings on machining.

We consistently strive to provide excellent customer service and provide all product services including technical advice to the customers. We constantly make an effort to increase productivity and quality.

We are convinced that in our production program you will find a solution that will help you not only when machining your products, but also to extend tool life and achieve savings during your machining.

Contact

Web: www.bonar-as.cz

E-mail: info@bonar-as.cz

Telefon: +420 583 223 730

IČ: 25 13 14 27

DIČ: CZ25131427

Address

BONAR a.s.

Čsl. armády 1018/58

Šumperk

787 01

Česká republika